Port of Hanko, completely carbon neutral since 2025

Port of Hanko Ltd. has entered a new era in its operations. From the beginning of 2025, the operations are completely carbon neutral.

Port of Hanko has long monitored its greenhouse gas emissions and their development. Emissions have been calculated since 2019 according to the internationally most used standard, the GHG Protocol. The calculation takes into account the seven greenhouse gases specified in the Kyoto Protocol (carbon dioxide, methane, nitrous oxide, and fluorinated gases HFC, PFC, SF6, NF3), which are often standardized into a single value, carbon dioxide equivalent, based on each gas’s climate warming potential.

The GHG Protocol divides emissions into three different sections, called scopes. Scope 1 includes direct emissions from own operations, with emission sources such as company-owned or used cars, machines, and backup generators that use fuel, or refrigeration equipment that may have occasional leaks. Scope 2 includes emissions from the production of energy purchased and used by the company. Scope 3, in turn, covers the entire company’s value chain emissions from the initial production of purchases to transportation and the emissions during the use of sold products. Often, scope 3 is the largest in terms of emissions, regardless of the company’s industry. While scope 1 and 2 emissions are relatively easy to reduce by switching to renewable fuels and energy sources or low-emission refrigerants, scope 3 emissions are more difficult to address as their emission sources are not directly under the company’s control. So far, only scope 1 and 2 have been considered in the port’s calculations, but scope 3 calculations are also being implemented.

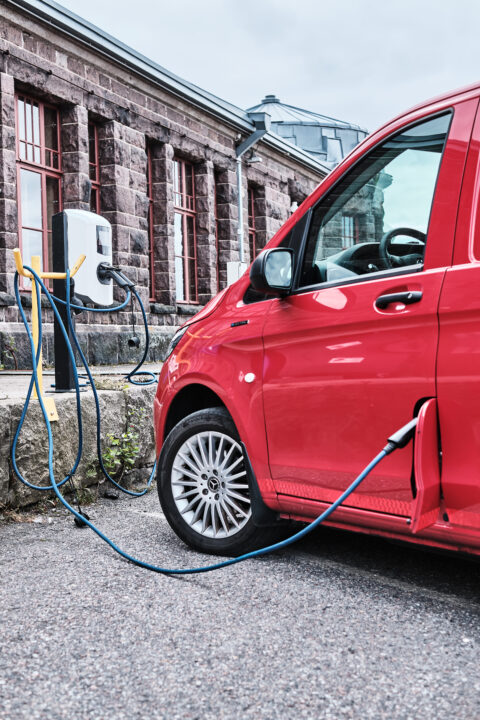

The company’s own operational emissions have always been quite moderate and have been systematically reduced by switching to renewable energy. Since the beginning of 2024, Port of Hanko has purchased only renewable electricity, and in the same year, heating systems were upgraded to water-air heat pump systems, and fossil heating oil was replaced with renewable biofuel oil. The use of regular diesel in the company’s own machines and equipment has also been abandoned, and renewable diesel is now used. Most of the company’s vehicle fleet is electrified.

The emissions that the company has not been able to completely eliminate with its own changes, mainly special machines and equipment and devices intended for preparedness, are offset with certified emission reduction units. Certified and verified emission reduction units are used for offsetting, which must be genuine, additional, and permanent.

This is a voluntary emissions trading scheme, through which the company achieves zero emissions and, on the other hand, increases long-term carbon sinks by directing emission reductions to biochar production. With biochar, carbon is bound to the soil for a long time, as it is used in soil improvement and as an absorbent in wastewater treatment. These emissions, which are offset, will continue to be reduced as corresponding technology develops.

Registry puro.earth/retirements – Port of Hanko

Cooperation with port operators also continues to encourage other operators in the port area to make their own emission reductions.